Single-chip colour cameras

Quite a few applications can only be solved using a colour camera.

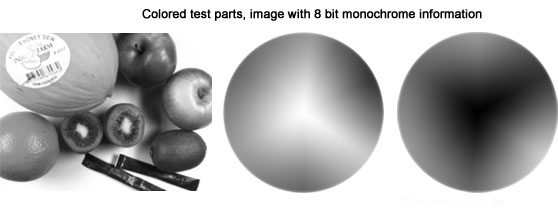

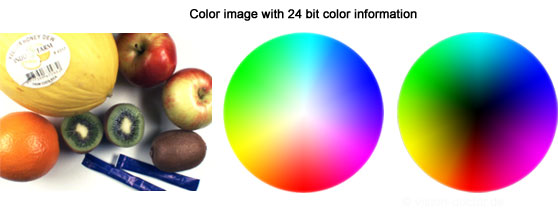

The information of a monochrome image, which can only differentiate 256 different shades of grey using 8 bits of grey scales, is absolutely suitable for many applications in order to detect errors, for presence checks and measuring tasks as long as there is sufficient brightness difference / contrast between the test areas. In the image below, the fruits, for example, can be clearly differentiated from the background. The shade of grey in the resulting image depends on the saturation and luminance of the colours, but also strongly on the reflectance of the surface.

|

Yet problems occur quickly when neighbouring areas are to be inspected and differentiated using similar brightness. Coloured test characteristics which would possibly have resulted in the same shade of grey when using a monochrome camera (e.g. light blue and light green) can now be clearly differentiated by means of the additional colour information.

|

Single-chip colour cameras can be used as a simple, cheap solution for these tasks: they are capable to provide essentially more information with 3 * 8 bits RGB. Theoretically, this amounts to 16.7 million different colour gradations.

A large number of colour camera versions are available on the market providing reasonable colour quality. In many cases they are not more expensive than the monochrome counterpart.

Typical use of colour cameras

- continuously changing colours of the test objects

- many different colours at the same time in the image which would not be differentiated otherwise

- depiction, rendition and recording of images as realistically as possible, just like people would see them, too

- monitoring, colour coding checks and colour shade measurements of objects

- print section / printed material

A large number of colour applications are solved using single-chip colour cameras. In case of critical applications which require a high colour fidelity and high colour shade differentiation, three-chip colour cameras are preferentially used.

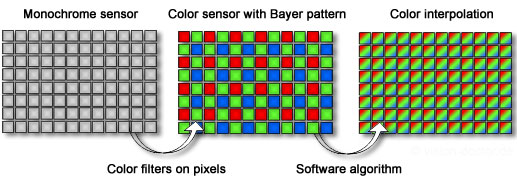

Functional principle of the Bayer mosaic

Compared to monochrome sensors, additional transparent colour filters are applied pixel per pixel. These filters have the effect that the individual light-active areas of the sensor respond differently to the wavelengths of visible light. As only red, green or blue colour components are given as information for each pixel, a software method must determine the missing colour components in order to obtain an "RGB pixel".

|

Compared to monochrome sensors, additional transparent colour filters are applied pixel per pixel. These filters have the effect that the individual light-active areas of the sensor respond differently to the wavelengths of visible light. As only red, green or blue colour components are given as information for each pixel, a software method must determine the missing colour components in order to obtain an "RGB pixel".

Colour image

Bayer raw image

Transmission of colour information

State-of-the-art industrial colour cameras can often transfer their data in different "colour formats":

- RGB: in case of an RGB camera, the Bayer colour conversion of the image is done on the FPGA of the camera electronics, the camera therefore transmits 24-bit colour information.

- YUV: in some cases, a YUV-coded signal can be sent for data reduction, which requires only 16 bits for the transmission.

- Bayer Raw: the lowest data rate, however, arises when the monochrome raw Bayer image is sent and is converted into colour information on a frame grabber card or by means of software on a PC.

Adverse effects compared to monochrome cameras

Colour cameras are used only where colour information is really required for evaluation. A great number of reasons are still indicative of the use of monochrome cameras:

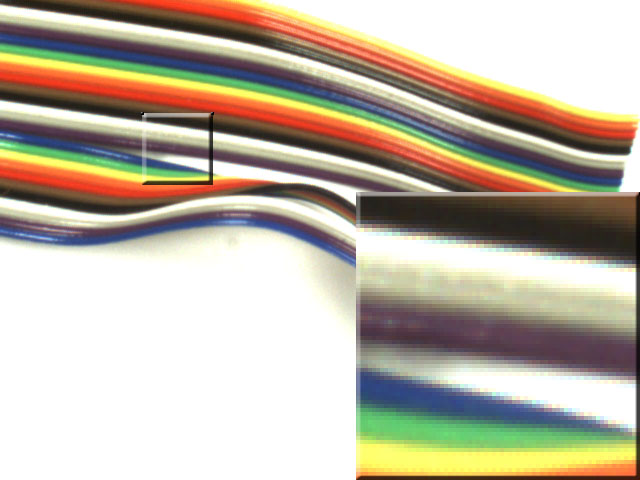

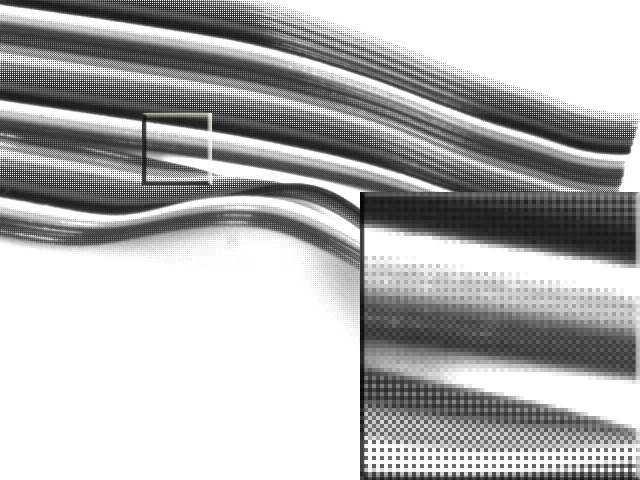

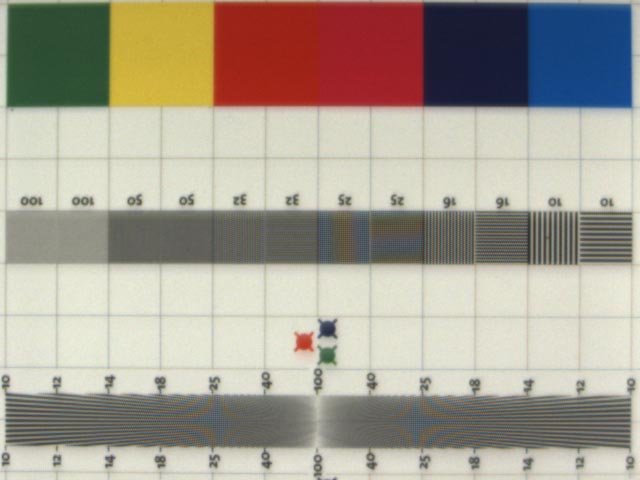

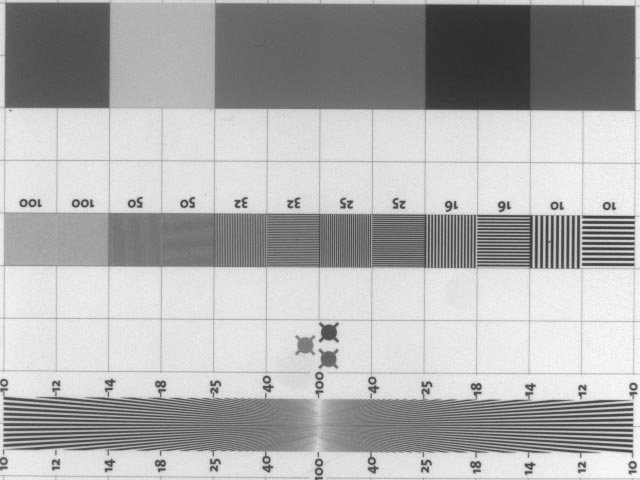

- Due to the colour interpolation of a single-chip colour camera, the user loses over 30 per cent of the resolution in case of fine details. Bayer interpolation results in edge effects and pseudo-colours on the object edges which are visible as distinctively coloured pixels. Using monochrome or three-chip colour cameras of the same resolution, smaller structures can therefore be detected. The measurement is always more accurate when using a monochrome camera (see grid lines and bar pattern in the images below).

- Depending on the data format, the image transfer rate and data quantity is mostly far higher than in case of a monochrome camera.

- High loss of light: the colour filters on the pixels reduce the sensitivity by up to 75% compared to monochrome cameras. This can be critical for applications which require a short exposure time.

- Workaround for monochrome cameras in case of coloured lenses of similar brightness: when using monochrome cameras, single colours of the test objects can be brightened or darkened using coloured lighting and can thus still be differentiated. In this way the use of a colour camera can possibly be avoided.

Colour image (single chip)

Monochrome image

Important for machine vision

- Colour camera sensors are typically equipped with a daylight band-pass filter which blocks UV and IR radiation in order to avoid faulty information. By using a halogen lamp as illumination, for instance, an extremely red-tinged image would be created as the IR radiation would be interpreted as additional "red". If such a filter glass is not mounted, you can also screw it onto your optics.

- In most of the cases, a camera does not detect the direct emission of light, but colours which are generated by absorption, remission, reflection, etc. of light on the part. If the surface of the part is tilted, the brightness of the colour may vary, which is detected by the camera.

- The incident light also strongly varies over the time after switching on the illumination: in case of fluorescent lamps, for example, there are clear brightness variations within the first 20 minutes of the switch-on phase of the system. White LEDs, too, show brightness effects when warming up after the switch-on.

- Each illumination ages, emits fewer and fewer light in the course of time and shifts its colour temperature over the time. This can also lead to shifts of the measured colour value during colour inspection. The stabilisation of the service life and colour temperature of the LED by means of a flash controller or the cyclic replacement of several lights in the lamp cluster or the early replacement of halogen and fluorescent lamps can help. An alternative solution can be a new white balancing and a brightness adjustment by correcting the exposure time of the camera.