LED illumination

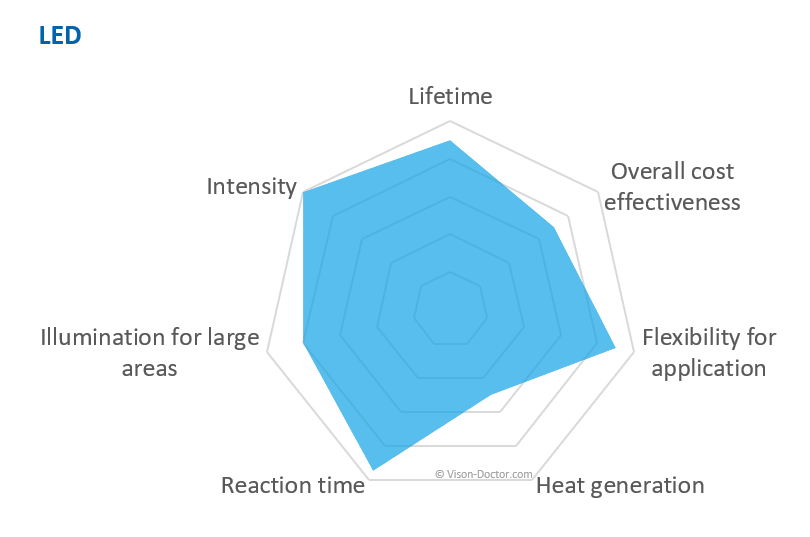

Light-emitting diodes, LEDs for short, have been used for approximately 10 years in industrial image processing. By constantly improving the semi-conductor materials, the intensity could be increased extremely. Today, LED lights cover a major part of industrial applications. Halogen and fluorescent lamps are only frequently used in applications which require large-area illumination, like robot applications or line scan camera inspections where much light and/or the illumination of large areas is required as well.

Reasons for the frequent use of LEDs

|

- low power consumption, thus low heat generation

- extremely long service life of 30,000 to 100,000 hours

- little premature failure; by means of a cluster of many LEDs, the failure of a single one is uncritical

- smallest dimensions, directional light due to the lens optics of the housing

- high shock and vibration resistance in industrial use

- well switchable or flashable to increase the service life or output

- applicable in various colours, not only white

- due to the small size, many different lamp designs and shapes are possible to realise different lighting techniques

Functional principle of the LED

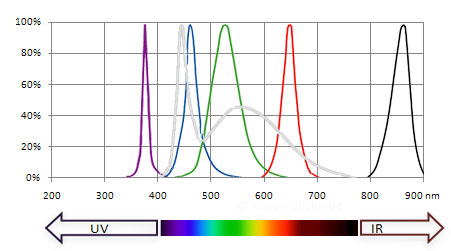

Electroluminescent diodes work like semiconductor diodes which generate light in forward direction. Light is emitted in this way. The abbreviation LED stands for "light-emitting diode". The energy and colour of generated light is determined by the semi-conductor material used and its doping. Mixed crystals such as gallium arsenide (GaAs), gallium arsenide phosphide (GaAsP), indium gallium nitride (InGaN), etc. are used.

The LED consists of a semiconductor material that is n-doped, on top there is a very thin p-doped layer which has a lack of charge carriers. When applying a voltage, an excess of charges is generated in the junction, which recombine with holes in the p-doped material and release their energy there. Since the upper layer is very thin, the light flash can emerge from the material. The light generated in this way is monochromatic due to the exactly defined energy amounts of the semiconductor material. As opposed to an incandescent lamp, the light always has one particular colour.

White LEDs, too, primary only generate monochromatic light. Only by means of a trick, white light is produced: The light of a 100% blue-emitting LED stimulates yellow fluorescent dyes, which are arranged around the light-emitting crystal. White light is mixed from the direct emission of blue light and the fluorescence of yellow-green and red light.

|

Typically optical elements bundle the emitted light beam to a defined cone of light.

The luminous intensity grows proportionally to the amperage, which is used in industrial machine vision in order to generate high quantities of light by means of high-power LEDs. A consumption of 5 - 25 watts is typical for an LED illumination. The energy yield can be increased even further if you increase the amperage over 100% of the permissible value. The LED would be damaged in continuous operation immediately. By means of a flash controller, however, short intense current pulses (1 per inspection) can be used to overflash to the triple to sixfold quantity in order to generate a multiple of the luminous power.

Important for industrial machine vision

- LEDs age much faster in case of strong warming than with sufficient cooling. The generated heat should be dissipated by means of air supply, thermoconductive mounting or useful triggering.

- Warming decreases the light yield. The brightness depends on the current flow and the temperature. Ideally use a flash controller / current limiter in order to keep the LED cool.

- Frequent switching (per inspection) does not harm the lighting, but extremely prolongs the service life.

- The service life of the LED is the age at which the LED emits only 50 % of its initial brightness. A total failure is very rare, the aging process of LEDs is almost linear.

- By using a flash controller, the intensity can be increased by several hundred per cent.

- Important for colour applications: even white LEDs change their colour temperature over their service life. Due to the aggressive exposure of the fluorescent dyes with plenty of light energy they age very quickly. The LED becomes more bluish. A recalibration may be required from time to time (but clearly less frequently than in case of halogen / fluorescent lamps).