Polarised light

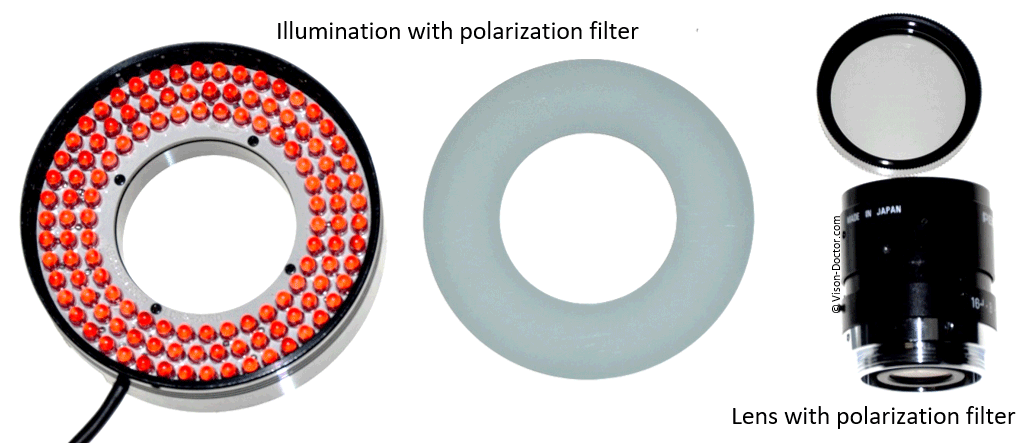

By means of a polarisation film in front of any industrial illumination, light can be polarised. There are flexible foils with a thickness of 0.25 mm to 1 mm available to the user. Thicker filters of 2 mm and more are typically delivered as hard plastic plates.

If you put an additional glass polarisation filter in front of the optics, the polarised light is selectively blocked or passed. The principle of polarisation and filter effect is described in detail in the chapter "polarisation filters". There you can also find further examples.

|

In this way interfering reflections can be avoided on:

- liquid surfaces, like water, etc.

- glass surfaces

- reflective plastic surfaces

- shiny metallic materials

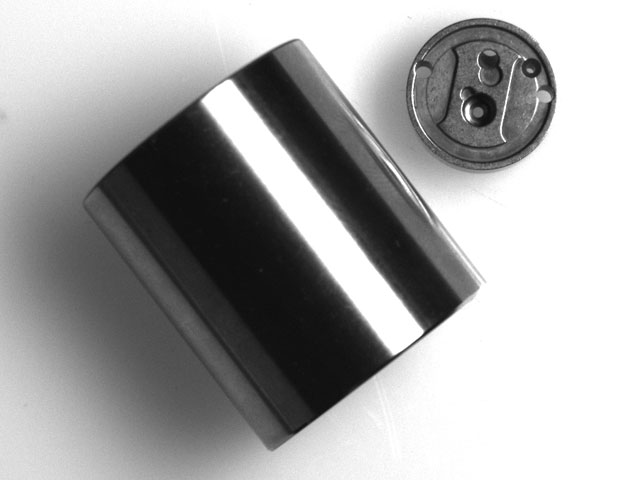

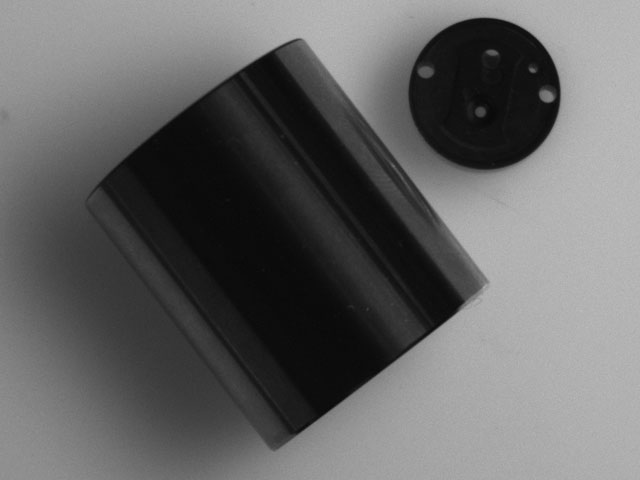

Example of polarised light and polarisation filter on the optics

Metallic sheen on metal surfaces can be suppressed by using a polarised source of light and a polarisation filter. The metal parts appear very dark in the camera image. Especially non-plane objects like cylindrical, curved metal surfaces or crinkled foils (aluminium blister, etc.), can usually hardly or very difficultly be illuminated in a homogenous way.

Diffuse illumination

Polarized light

Depending on the position of the test objects in the inspection area, these reflections would "move" strongly on the surface. A taught object can then look very different to the inspection software: this leads to misinspections. These difficulties are avoided by using the mentioned illumination and filter technologies.

Unpolarised light

Polarized light

Tips for handling polarisation films in front of the illumination

- If there are prefabricated polarisers and mounts for the illumination, you can save a lot of cutting and mounting work. Especially ring-shaped cuts with a hole in the middle are difficult.

- Keep a certain distance between hot light sources and the foil. The chemical molecules which serve as dyes are sensitive to heat. From approximately 70 °C on, the foils can decompose.

- The thickness of the film has hardly any influence on the polarising effect. However, thicker films better keep the shape and are often easier to mount in front of an illumination.

- Please only use special glue for polarisation films.

- Typically, common polarisation films are active between 400 and approx. 780 nm. They are therefore NOT usable for infrared lighting. Buy special foils!

- The transmission of polarisation films without an elimination effect due to a second filter in front of the optics is already reduced by 35 to 40%. The filter in front of the optics strongly reduces the quantity of the transmitted light again. If re-adjusting the exposure time and aperture does not provide a remedy, use an LED illumination with flash controller.

- Laser light is normally already linearly polarised.