Influence of the test object

Even when using the same illumination technology, especially the test object itself has the greatest influence on the resulting video image to be evaluated subsequently.

Responsible for this are factors such as:

- Interactions of light with the material characteristics (plastic, metal, glass, ceramics, etc.)

- Surface texture (parallel brushing, circular brushing, grooved, porous, smooth, rough, fibrous, etc.)

- Surface geometry (planar, stepped, sloped surfaces, spherical, cylindrical, etc.)

- Material colours colours (transparent, semi-transparent, white, red, green, ..., black)

Benefit for the user

It is the aim of the image processor to use the surface and material properties of the inspected part in such a way, that, in combination with a perfect lighting technique, as much contrast as possible is created while avoiding interfering reflections.

Direct illumination

Diffuse illumination

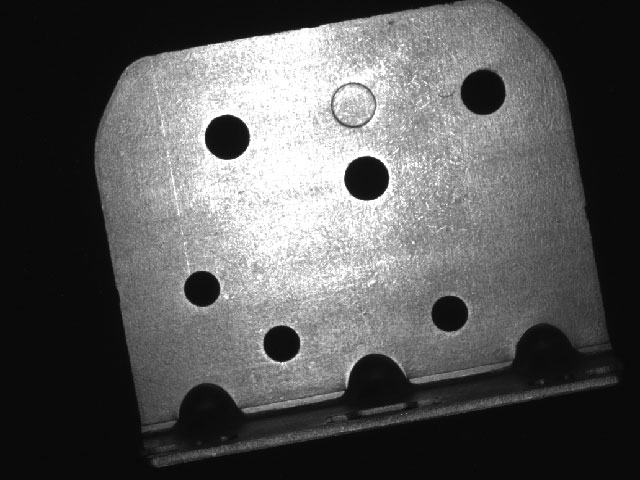

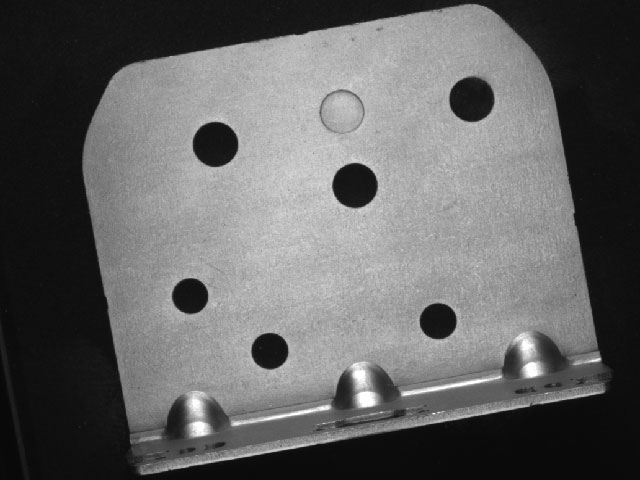

Images: metallic glossy work piece difficult to illuminate, even surface for the most part.