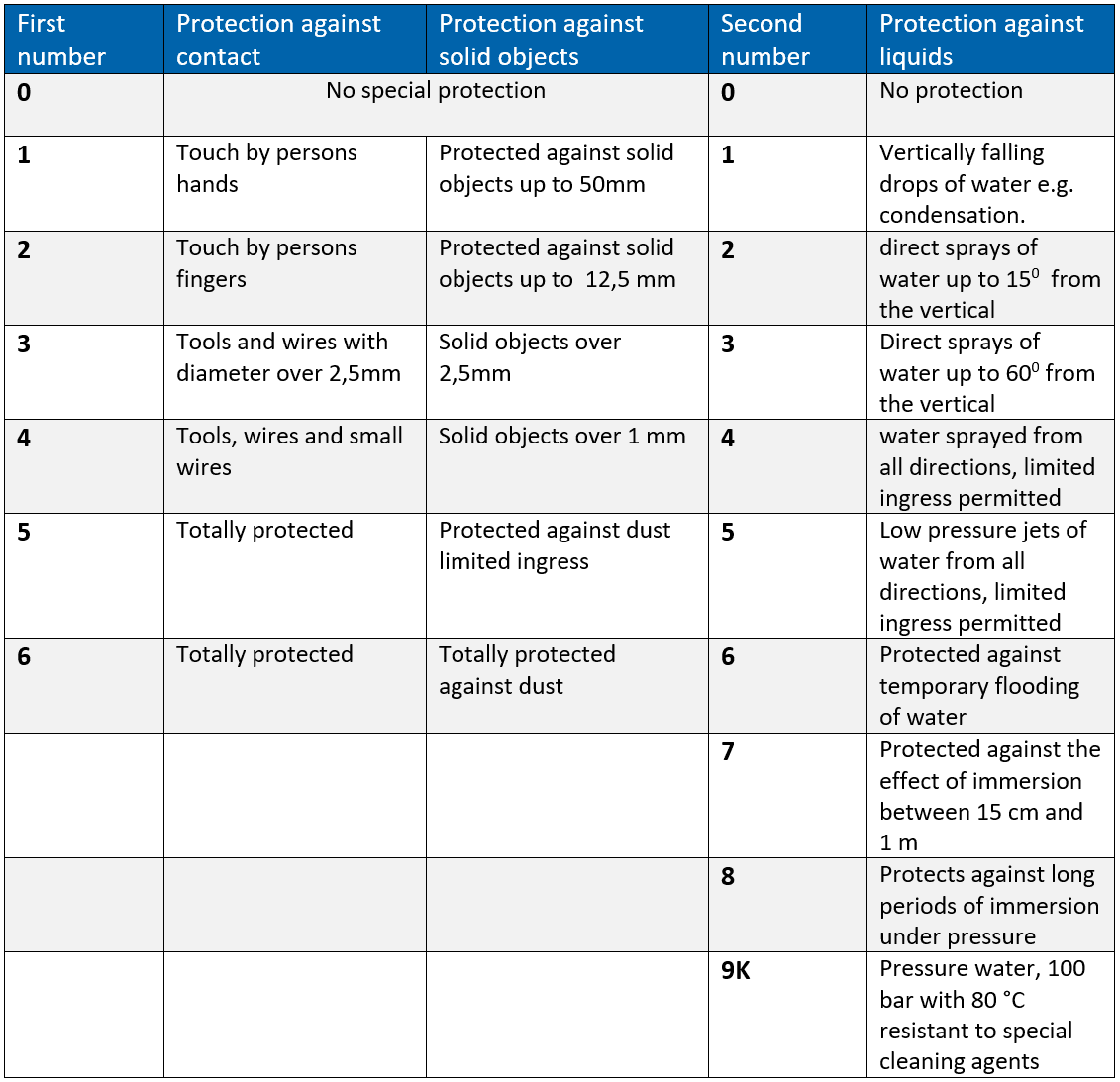

Protection classes

Image processing components are often used in harsh environmental conditions and as electronic components they require corresponding protection. Since this is not provided for the individual components, such as a lens, LED lighting or industrial camera, an appropriate protective housing must be used. But also people must be protected from possibly harmful emissions. Lasers and lighting can be harmful to people because of their intense light beam. IP protection classes and laser safety classes define appropriate measures of protection.

The IP degrees of protection define the

- protection of persons against access to hazardous parts inside the housing

- protection of the equipment inside the housing unit against ingress of solid foreign bodies

- protection of the equipment inside the housing unit from harmful effects due to the ingress of water

|

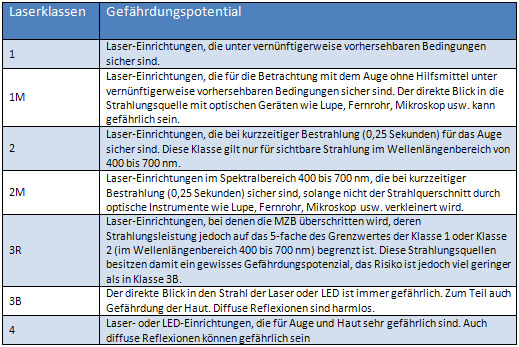

Laser protection class

|

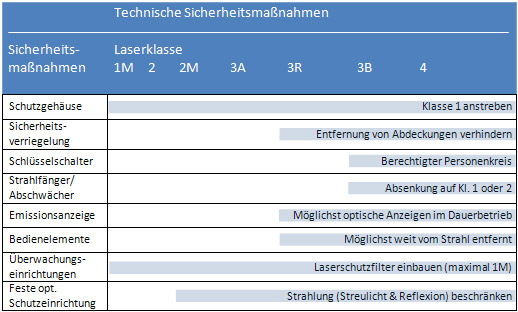

Special structural measures, safety notes, protective clothing, safety officers are not required, but from class 2M on, the light beam must be timed and reflections must be avoided.

Only from class 3 on, the effort must be increased. Warnings, protection areas with safety shutdown, suitable protective clothing, safety officers may be necessary.

- shield the light beam

- limit the field

- restrict the light energy to the actually required quantity (power control or timing)

- limit the reach of the light emission (reflections, stray light) by means of housing or beam timing

- secure the access to the system in case of higher safety classes and to switch off the light when opening the protective area. Personal protective equipment (e.g. safety goggles) may be necessary, a security officer is required in the company.

|

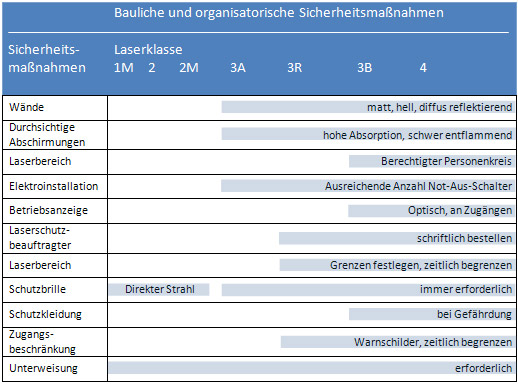

Structural and organizational safety measures

|

Important:

Exact details for each safety class are defined in the respective directives. The basis is the accident prevention regulation "laser radiation" (sec. 6 of the regulations of the Association of Occupational Accident Insurance Funds) and DIN EN 60825-1 (VDE 0837 Part I) until version 03.1997. The tables shown here cannot list all particularities for reasons of clarity.

Please thoroughly acquaint yourself with current safety regulations, the information presented here only provides a thematic overview. No liability assumed for the correctness of the information!