Specification of a machine vision system

Before a system is selected, you should clearly define all your requirements for the machine vision system. Not all criteria can be met by all system types so that the choice is quickly narrowed down to the appropriate test system. The Starting point for this consideration is the object to be inspected and the process environment in which the system must be installed. Detailed knowledge of this is essential to establish a stable plant process and to implement an economically viable application. The complete "practice" section of this website is supposed to help you in making the right decisions. In particular, the section "Specification sheet" provides an additional list of questions.

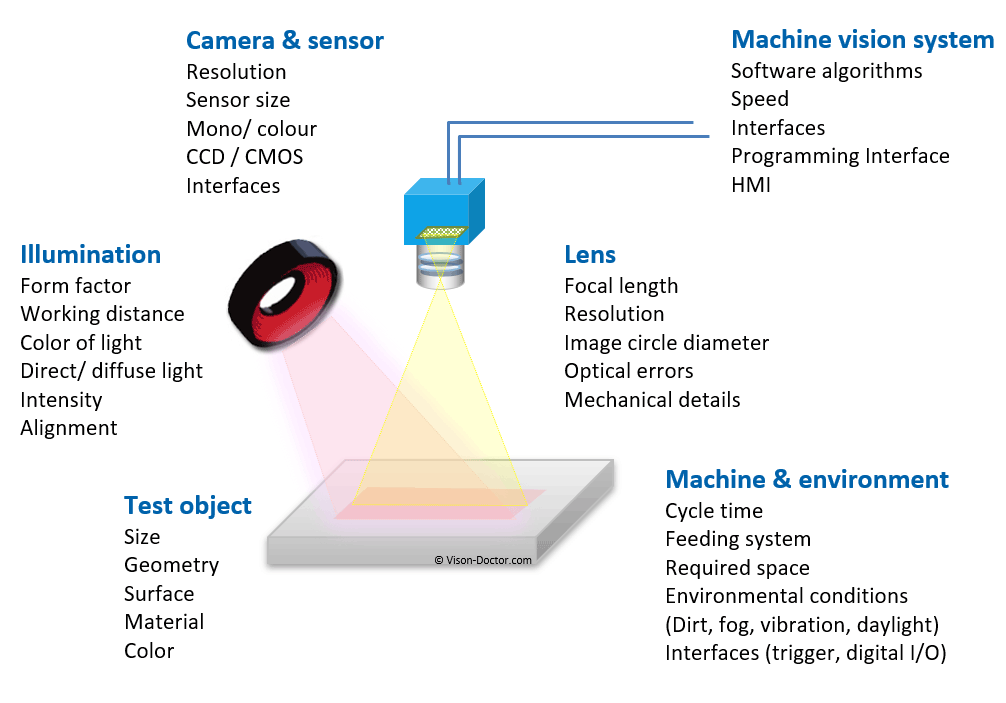

A variety of basic conditions and parameters must be weighed for the selection of the image processing system:

|

Important information on the test object:

- How big is the object? How big are the recognisable features? Is a colour camera necessary for detection? How precise must the measurement be? The selection of the perfect camera (resolution, sensor type, etc.) depends on this information.

- How far must the image processing system be arranged from the object? Can I inspect from up close or is a handling system (robot, rotary table, linear axis) in the way? Working distances with known resolution and size of the camera sensor and object allow for the calculation and selection of the perfect lens.

- Which surface and shape does the inspected part have? What material is it made of? Which colour does the object have? By selecting the perfect lighting, defects and objects can be made visible by creating a contrast to the environment.

- How are the characteristics made visible in the camera image? How good is their contrast to the image background? Depending on the task (measuring, counting, presence checks, identification, print inspection, object search, optical character recognition, code reading), different software tools are required. The system must provide the appropriate software tools to solve your application!

Important information on the process environment

- How many parts per second must be checked? Possibly also simpler systems can fulfil these tasks, however, they may not be fast enough.

- How does the feeding work? How fast? Which tolerances in X / Y and Z-axis appear? The software tools must be able to compensate them.

- How much space in the system is available for the inspection cell? Weight and size of the camera (and the lighting) can be important in many systems.

- The process environment (dirt, dust, debris, electromagnetic interference, vibrations) can be strongly disturbing. The image processing system is supposed to be supplemented by appropriate accessories, like protection enclosures, to avoid environmental interference

- How should communication be effected? Which interfaces are required? Must the data be recorded? Is there a need to store images in a database? Which user interface for the staff (HMI) is required? Not every system provides the right possibilities. Please also consider the required cable lengths! Not every interface or protocol is capable to communicate over longer distances.

Superior questions for the camera selection

- What budget has to be respected?

- Who will integrate it into the system?

- Operation in everyday life: How easy is it to handle the system?

- Who maintains the system? How can new component types be taught?

- Who takes over the system maintenance?

Conclusion:

Many questions must first be answered before you can decide which camera system is able to fulfil your tasks. For this purpose the camera system must never be treated alone, but it is also considerably defined by the underlying conditions (inspected part / plant). Only the successful selection and the interaction of ALL individual machine vision hardware components together with the software ensure success!