Light plays a central role in industrial image processing: It is not the object itself that is inspected, but only the visual image of the object! This means that only homogeneous lighting conditions produce a consistent image of the same object.

Fluctuating lighting conditions should therefore be avoided at all costs!

Ideally, lighting should be used to create a perfect light/dark contrast.

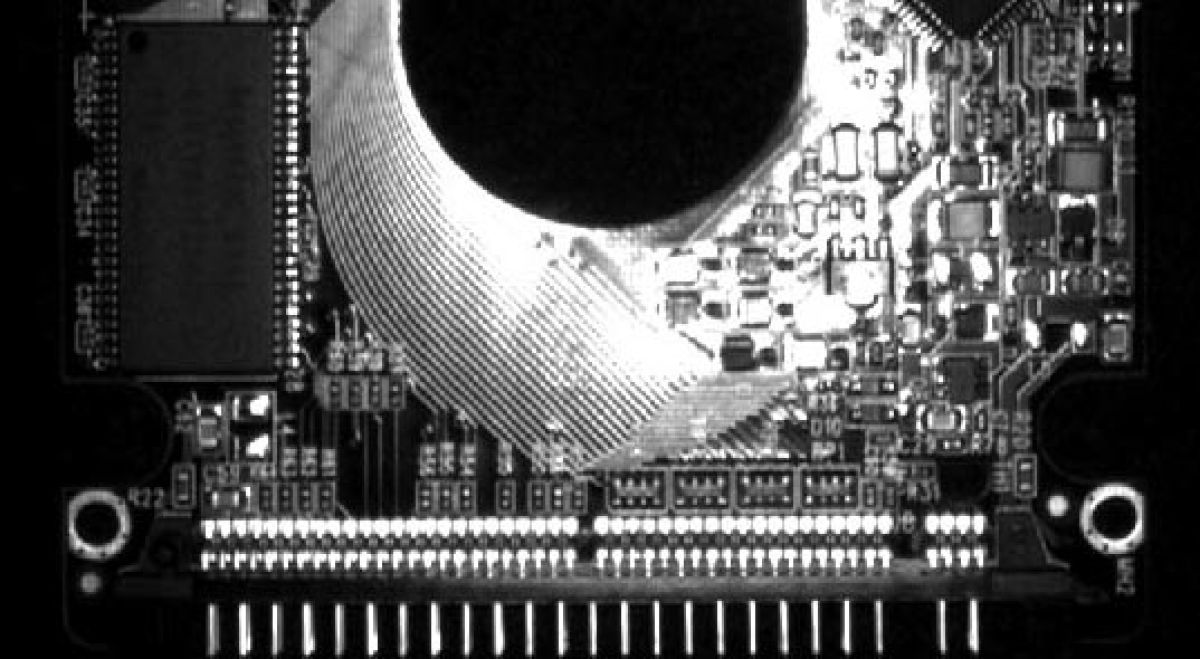

Surface partly very bright but overexposed, partly dark due to total reflection.

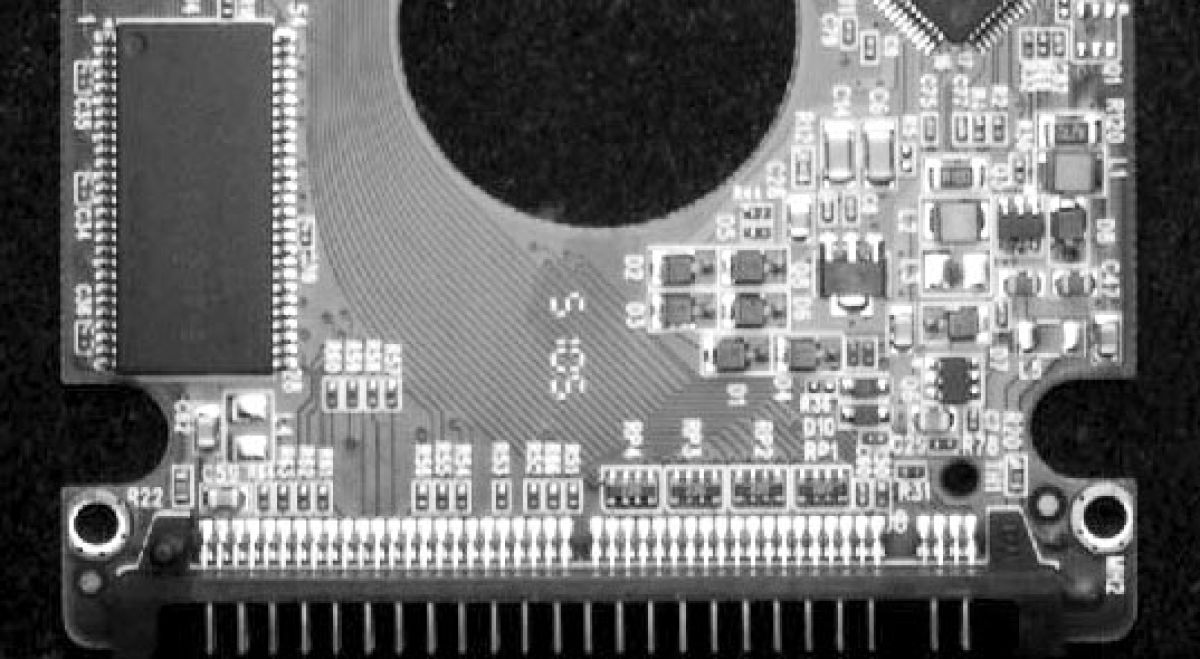

Surface smoothly illuminated due to homogeneous incident light.

Lateral edges are very bright. Scratches and dust are visible.

Part appears as black silhouette only. No surface information, contours ideal for metrology applications.

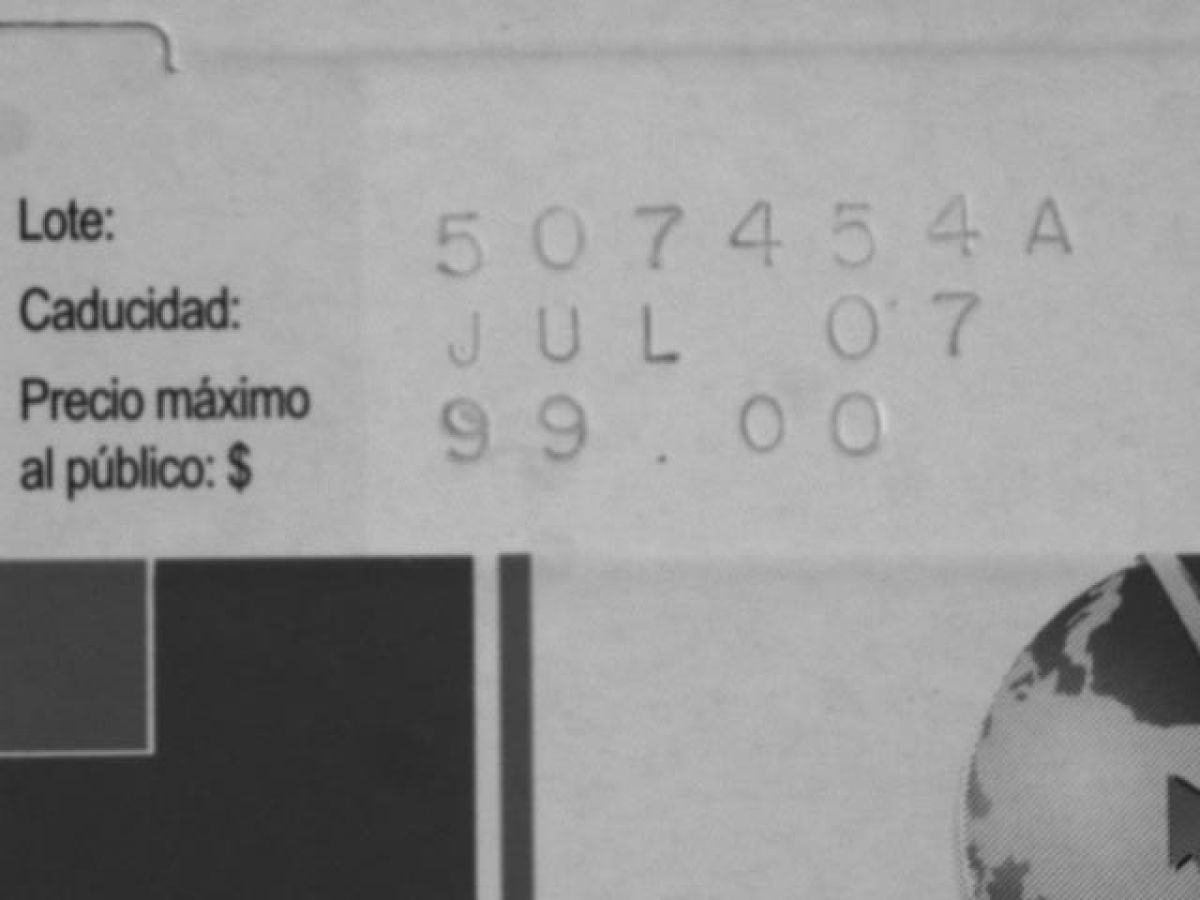

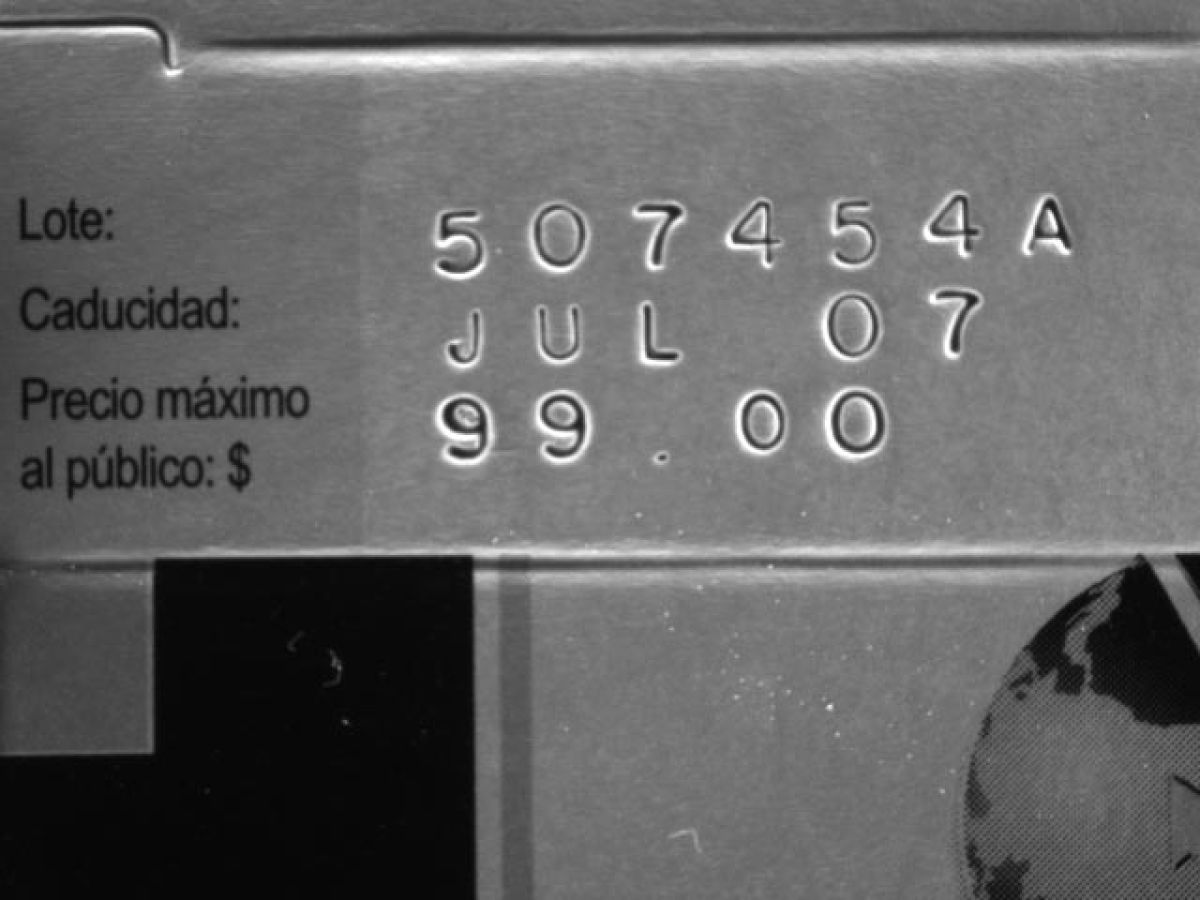

Diffuse light causes matte surfaces with low contrast of stamped font

Low angle illumination causes emphasis on the edges and instamped font

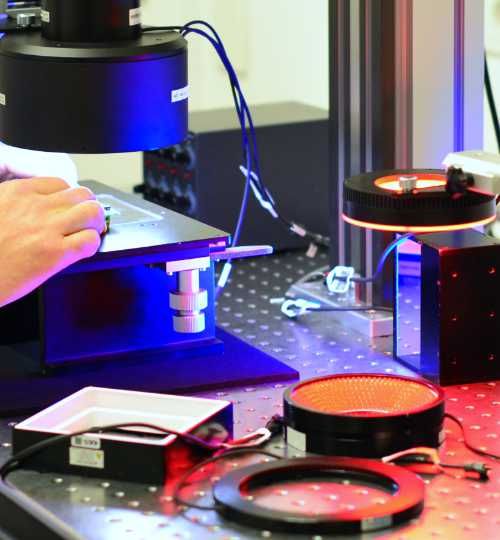

The key role is played by light and its interaction in a chain of effects between lighting, test object and camera.

Since the physical properties of the test object cannot be influenced, or can only be influenced to a limited extent, the object determines the lighting and the camera! The camera in turn defines the optics with its working distance and connection thread, and its data format and data rate also determine the image capture map.

It is worth taking a closer look at light and how it interacts with the material and the camera!

Vision-Doctor.com is a private, independent, non-commercial homepage project and not a technology provider or system integrator. Suitable technologies and further professional support can be obtained from the companies & partners listed below.

If necessary, I will be happy to provide a quick recommendation, contacts and brief information.