In the early 2000s, halogen lamps were mainly used in machine vision applications where large areas had to be illuminated using incident light spotlights, or where a lot of light was needed, such as for line scan camera applications. Today, LED lighting is used for all of these applications. One of the few areas where halogen lamps are still used today is in hyperspectral applications.

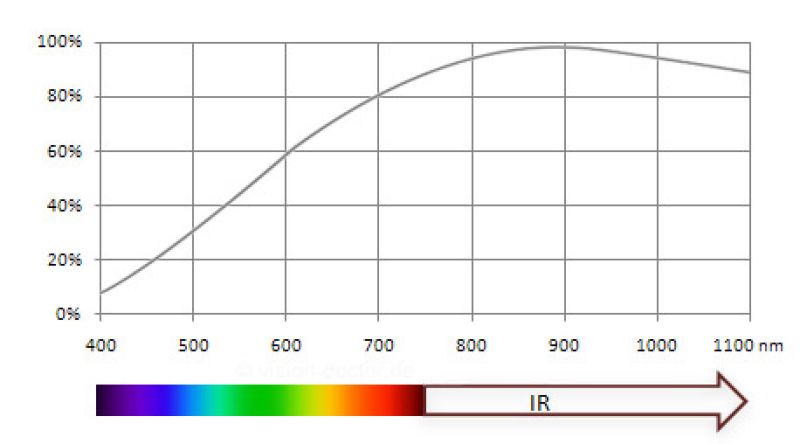

The continuous blackbody radiation spectrum, and in particular the spectral emission in the infrared range, is difficult to achieve with LED lighting. Hyperspectral sorting applications in the food sector (food sorting) or in waste separation are usually fast conveyor belt processes. High power of several hundred or thousand watts is required for high speed sorting.

Electromagnetic light can easily be generated by heating a body. In the case of a halogen incandescent lamp, this is done by means of a live conductor in an inert gas atmosphere so that the lamp does not burn up immediately. The brightness of the lamp depends on the melting point of the metal being heated.

A tungsten filament with an approximate melting point of 3420 degrees Celsius is normally used. Typical temperatures are around 2800 Kelvin, far from daylight at around 6000 Kelvin. Halogen additives ensure that the material evaporated from the filament is transported back to the filament. As a result, a halogen lamp is even brighter than a normal incandescent lamp and usually lasts longer.

In general, such light sources always have a spectrum similar to that of a blackbody radiator. This bell-shaped spectrum extends well into the infrared range and inevitably merges with heat radiation. A high heat output is therefore typical of this type of lighting.

Vision-Doctor.com is a private, independent, non-commercial homepage project and not a technology provider or system integrator. Suitable technologies and further professional support can be obtained from the companies & partners listed below.

If necessary, I will be happy to provide a quick recommendation, contacts and brief information.