Resolution of sensors

Common sensor resolution of industrial cameras has increasingly enhanced over the years. Due to enhanced production processes, smaller pixel structures can be realised today which are equally light-sensitive as the former large sensor pixels. The quantum efficiency of the pixels has been enhanced significantly. Today, sensors with a resolution of 2, 5, 8 or 12 megapixels are used, where cameras with 1 megapixel were used 5 or 10 years ago.

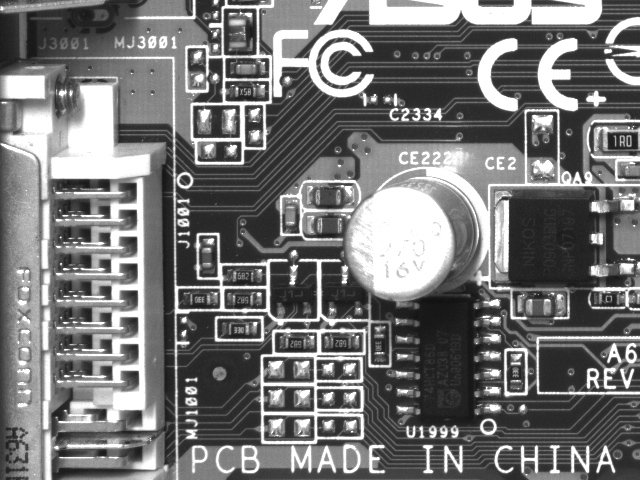

Image using a 5 mpix camera

Image using a 2 mpix camera

Image using a VGA camera

Sensors for C-mount cameras

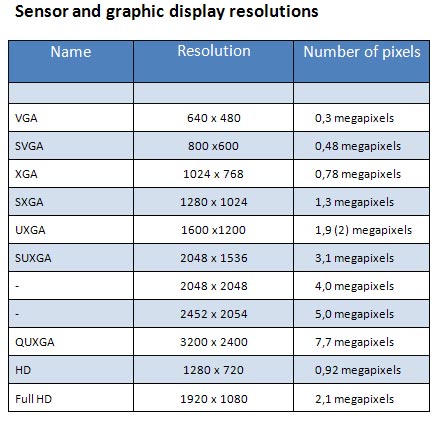

Common sensor resolutions for C-mount cameras are mostly between VGA resolutions (640 x 480 pixels) with 0.3 megapixels and sensors with 5 megapixels.

|

Sensors for F-mount and M42, etc.

Higher resolutions of approximately 12, 16, 20 or even 29 megapixels (or much more), as they are used today in consumer cameras, are not available for C-mount cameras in machine vision because the individual pixels are far too small and the image noise is far too strong in order to measure and inspect in high quality.

Resolutions of 12 to 29 megapixels are mainly realised with very large sensors which, due to the large image circle diameter, require F-mount optics (Nikon bayonet), M42 or Canon-Mount (EF-Mount) for example. They are often used for PCB layout applications and board inspections in order to detect even small features of rather large component groups and to evaluate them.

Line scan camera resolutions range from 512 pixels to 12288 pixels ("12 K line") in standard products today and have a line frequency of approximately 23 kHz. Within one second, image blocks of 12288 * 23500 pixels can be detected in this way, i.e. over 280 megapixels per second! Such a line scan camera sensor with a 12K resolution already has a length of 61 mm in case of a pixel size of 5 μm!