Optic coatings & spectral transmission

A high translucence is important for modern imaging lenses. Due to small camera pixels, a lot of light is needed. Many C-mount lenses comply with this trend having fast F-stops like f/1.2 or f/1.4. However, a high spectral transmission of the lens is also important.

Optic coatings - reflection avoidance

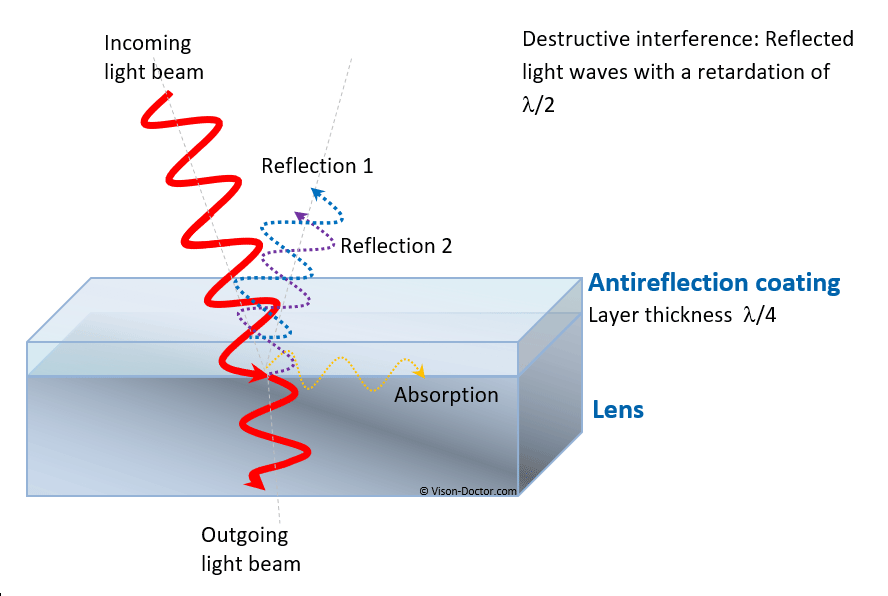

When the light penetrates the glass lenses, there are losses: there are light reflections on the surface, absorption within the material, as well as reflections on the light exit surface. The transmission rate defines the entire light exiting the material, which normally consists of directed and scattered portions. The transmission rate of normal glass is only 95 per cent.

By means of high-quality optic glasses and coatings, the impairment can strongly be reduced. For this purpose, (ideally) several very fine layers of metallic compounds are evaporated onto the surface as anti-reflection coating. They are visible to the naked eye as greenish or reddish shimmering coatings. The layer thickness and the material are selected in such a way that the reflections which appear at the individual boundaries interfere with and eliminate each other (destructive interference) and that rays of light passing through intensify each other.

|

As single interference layers only work for certain wave ranges of light in an optimal way, a large number of these layers must be evaporated onto high-quality glasses in high vacuum.

This, among other things, explains the price differences between simple and high-quality lenses. The loss of light of 4 - 5 % of uncoated lenses seems to be harmless in the first place. As one lens, however, often consists of 4 - 7 lenses, these values strongly add up. The resulting stray light is extremely disturbing for imaging applications and significantly reduces the image contrasts.

Spectral transmission

The translucence of the optic glasses is also called spectral transmission. As described before, it depends on the absorption and reflection properties of the glasses and coatings, but also very strongly on the wavelength of the light. The lens design of normal imaging lenses are mainly calculated and corrected for the visually perceivable range of light from 400 to 700 nm.

For the inspection with UV radiation, crown and flint glass lenses can no longer be used. The translucence of these common glass types extremely decreases from 350 nm on, at approximately 310 nm the transmission is less than 5 per cent. Only the use of fused quartz lenses provides a remedy. Their spectral transmission only significantly decreases from a wavelength of 180 nm on. However, the production of fused quartz lenses is technically complex and very expensive so that such lenses are only used in special applications.

For inspections with IR radiation, too, it is important to make sure that the optics has a high spectral transmission in this range. The glasses may be well translucent in near infrared, but the optic coatings for the avoidance of stray light (anti-reflection layers) must in particular also be adapted to this wavelength. Without these wide-range anti-reflection coatings, the stray light portion would increase extremely in the IR range.