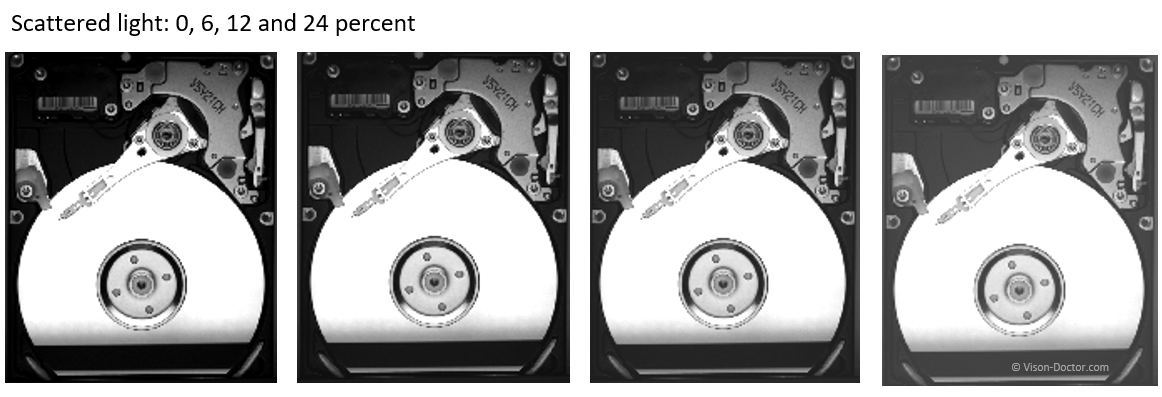

Stray light

Stray light is generated at every surface where light passes into another material of different optical density, e.g. from air into glass. The stray light portion per surface is approximately 5 per cent, with 5 - 7 lens systems in one optics, this portion can add up to greater values.

The results are losses of light and a reduction of the image contrast. A loss in brightness could possibly be accepted in a machine vision application, a significantly worse image contrast, however, usually leads to more inaccurate measuring results and detection rates.

|

By means of the respective anti-reflection coatings on the glasses, thorough matting of the lens edges and coating of the interior housing of the optics, stray light can mostly be avoided.

Important for machine vision

- High-quality optics, use of high-quality glasses and anti-reflection coatings are indispensable!

- Anti-reflection coatings are defined for particular wavelength ranges. Especially in the infrared range, many optics are not optimised in this respect. IR images which are captured using standard optics often appear "poor in contrast" due to the stray light difficulty. Use optimised IR lenses!

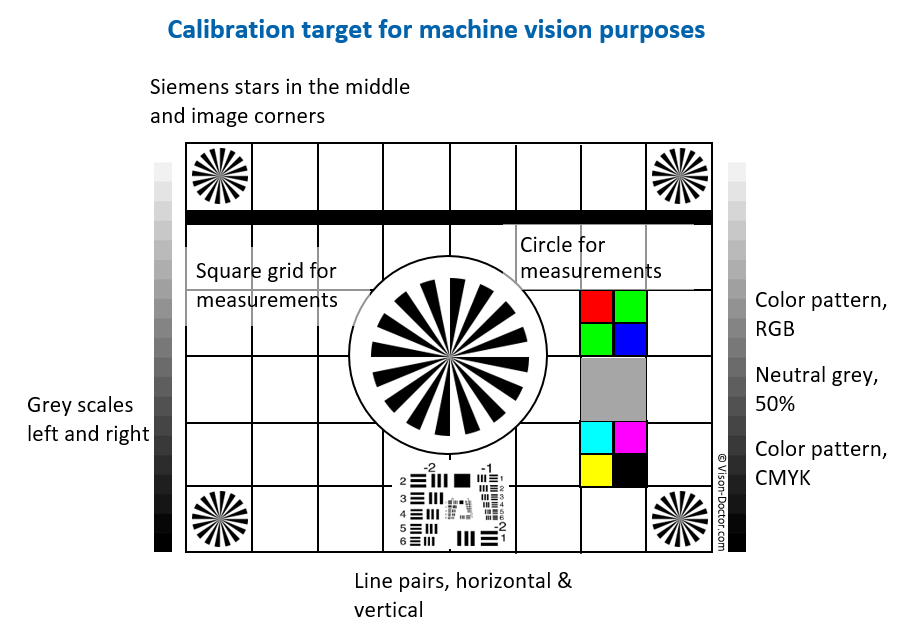

- In some cases, slight losses of contrast are not visible to the eye. Use your image processing tools (brightness measuring / statistics tools) and the histogram as an aid. A standardised test chart with grey scales helps to correctly assess the image contrast of the individual colours and shades of grey.

|