Optical errors

A large number of optical errors can occur in the lens system almost all of which essentially disturb the imaging process:

- Especially bad for the image processor are geometric distortions which cause an asymmetric curvature or compression of the image.

- Classic imaging errors are spherical and chromatic aberration, coma and astigmatism. They lead to blurred reproductions on the sensor.

- Further optical errors are caused by vignetting, high portions of stray light due to missing coatings and too little MTF. They typically result in a reduction of contrast in all or certain areas of the image. The image is therefore "poor in contrast" which causes more instable applications and less precise evaluations.

As a general rule almost all optical errors...

- disturb the image processing

- can seldom be compensated in the software with reasonable effort or not at all

- can mainly be avoided by using high-quality lens designs.

Partial correction of optical errors by means of stopping down

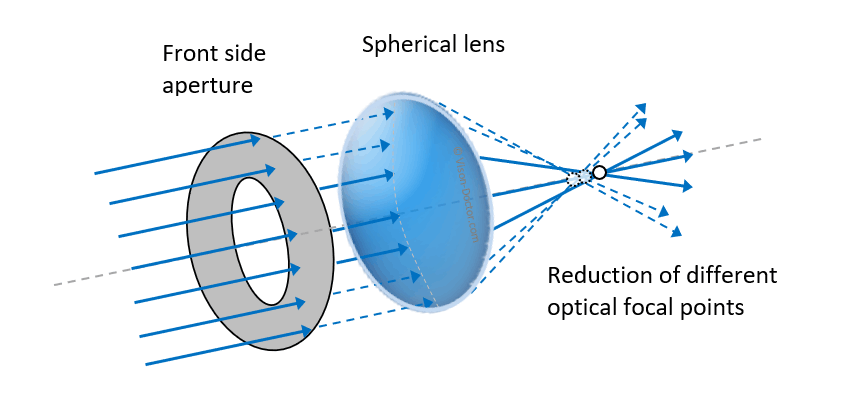

By cutting off marginal rays (artificial vignetting of the optics), certain imaging errors on spherical lenses such as chromatic longitudinal errors, spherical aberration, coma and astigmatism are reduced when stopping down. In this way the quality of the optic image is enhanced, as focus differences and other blurred imaging forms are avoided.

table class=myclass width=100%>Stopping down the lens: reduction of spherical aberration

Optimum imaging results are mostly achieved using an aperture of 5.6 to 8 in case of entocentric lenses. Further closing of the aperture intensifies the increasing effect of light diffraction at the mechanic slit of the diaphragm, which in turn may result in a visibly reduced sharpness of the image.

Conclusion:Do not economise on the optics and select high-quality lenses! A good selection and the interaction of ALL individual machine vision hardware components together with the software ensure success. Preferably error-free optics are absolute prerequisites for high-quality inspections!