Optic distortion

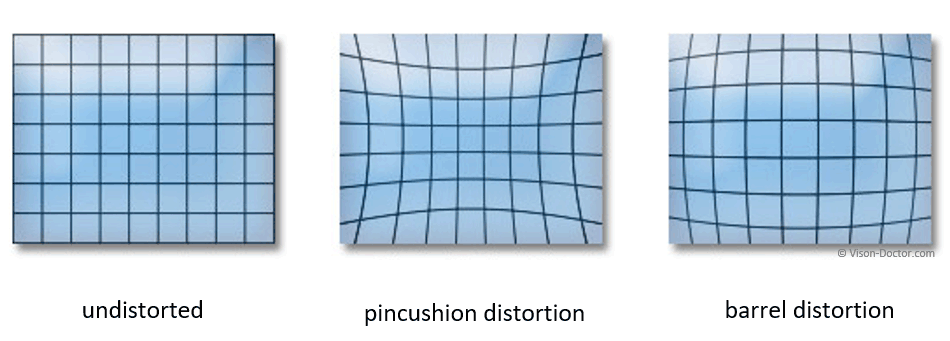

Distortion is a rotationally symmetric image error which increases from the centre of the image towards the image margin. In the course of this there is a local modification of the image scale within the image plane, which can be very disturbing for measuring applications. If the magnification rises towards the margins of the image field, a square is distorted in a cushion-shaped way. In the reverse case we speak of barrel-shaped distortion.

|

Wide-angle lenses in retrofocus design (back focal lengths greater than focal length) tend to generate barrel distortion, telephoto lenses (overall length below focal length) tend to generate pincushion distortion.

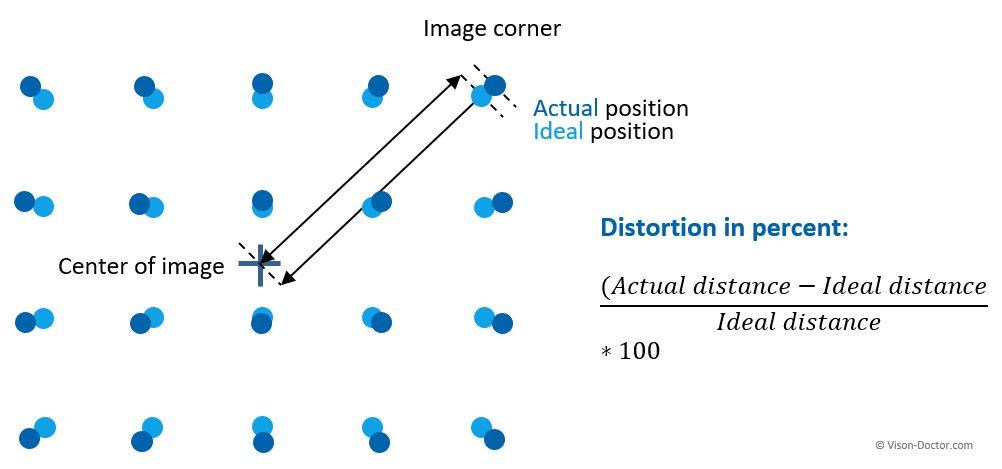

Determination of optic distortion

The percentage of the maximum distortion is measured from the centre to the image corners, as this is where the maximum distortion appears. In clearly simplified terms, the increase of the error can be described as linearly increasing from the centre of the image to the image margin.

|

- If the error is smaller than the pixel size of the camera sensor, it cannot be detected by means of measurements.

- The human eye is capable to perceive distortions only if the geometric error exceeds two per cent. But this might already be much too high for many applications! It is worthwhile to determine the distortion by means of measurements!

- This error occurs when using many common lenses and in particular when using wide-angle lenses. By means of elaborate lens designs it can mostly be corrected, though this is very expensive in case of wide-angle lenses.

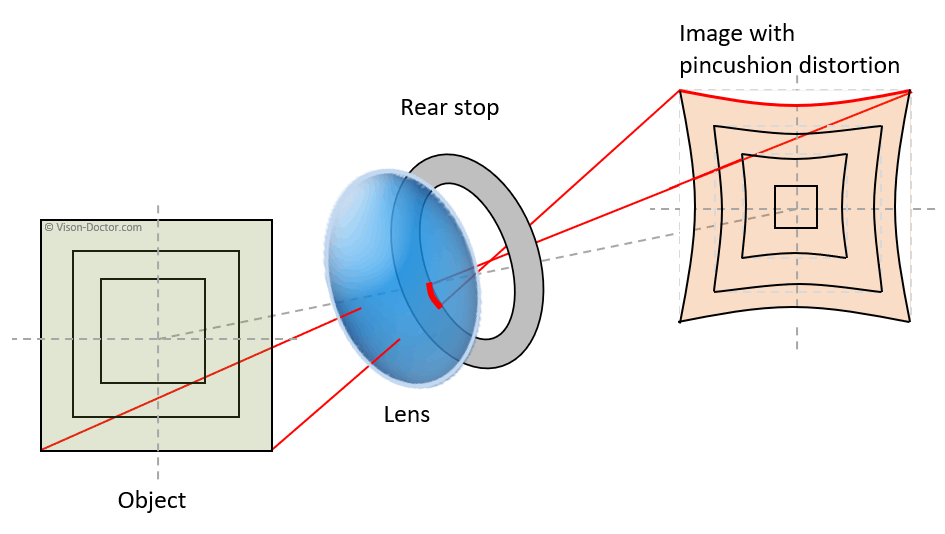

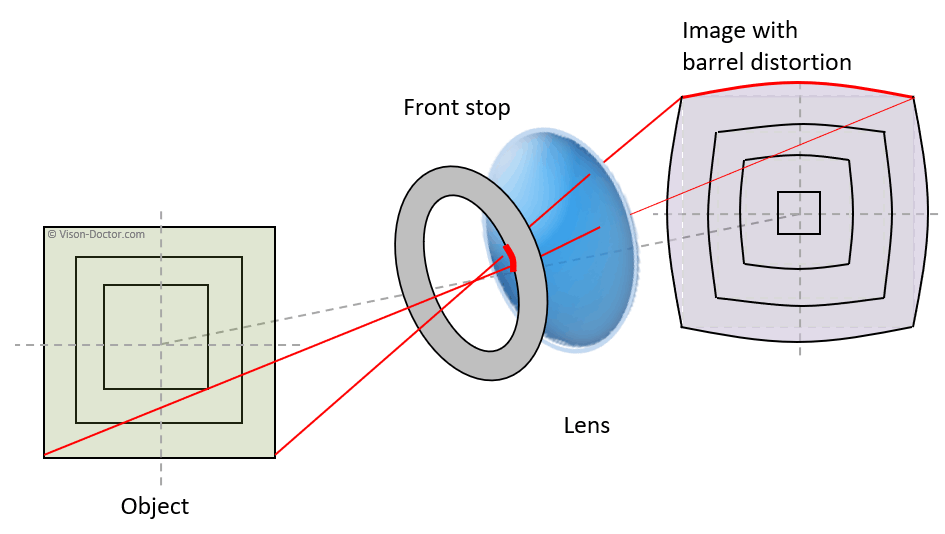

Origin of optic distortion

A non-symmetric design of the lens and an aperture before or behind the optic centre of the lens lead to image distortions. The image can be curved in a barrel-shaped or cushion-shaped way.

The back-side aperture assembly of a non-symmetric lens design leads to pincushion distortion:

|

The front-side aperture assembly of a non-symmetric lens design leads to barrel distortion:

|

Especially when using zoom lenses, this error can become very intense in case of long focal lengths, since lens groups but not necessarily the location of the aperture can be shifted.

Correction possibilities and tips for machine vision

- Enhancement by the user: downstream software correction (non-linear image distortion correction by means of image transformations) can additionally optimise the image.

- Use of high-quality corrected lenses with enhanced lens arrangement

- Application of longer focal lengths if a larger working distance can be realised as an alternative to wide-angle optics designs.

- No use of zoom lenses fraught with compromise

- Stopping down the optics does not correct this error.

Applications with extreme optic distortion

In almost all applications, distortion is disturbing. The extreme fisheye perspective of a very short focal length, however, can help in case of very close distances to look at the sides of a cavity. Typical examples of this are inspections of bores, needle roller bearings, thread pitches, etc.