Types of illumination

Even "white" light can be generated in many different ways. Depending on the problem, light requirements, object size, installation dimensions etc., different lighting is used:

- Halogen incandescent lamps

- LED illumination

- Fluorescent light (high frequency)

- Metal halide light sources (as "cold light" sources with fibre optic transmission)

- Xenon strobe lamps and metal halide lamps are used quite rarely in industrial machine vision.

A special role in image processing plays LED lighting. Its characteristics such as durability, mechanical robustness, ideal arrangement capability in almost any housing shapes are ideal for machine vision purposes. Its light colour is not only white, but also red, green or blue, infrared or even ultraviolet. This allows for applications which would not be possible using other types of illumination. Therefore, many industrial machine vision applications are realised using LED illumination.

The concept of colour temperature

Not every white light source seems to have the same shade of white for the viewer. In case of colour (as well as monochrome) camera systems, it can also be observed that the images have colour effects, or that grey values are shifted significantly.

Daylight

White LED

fluorescent lamp

Halogen lamp

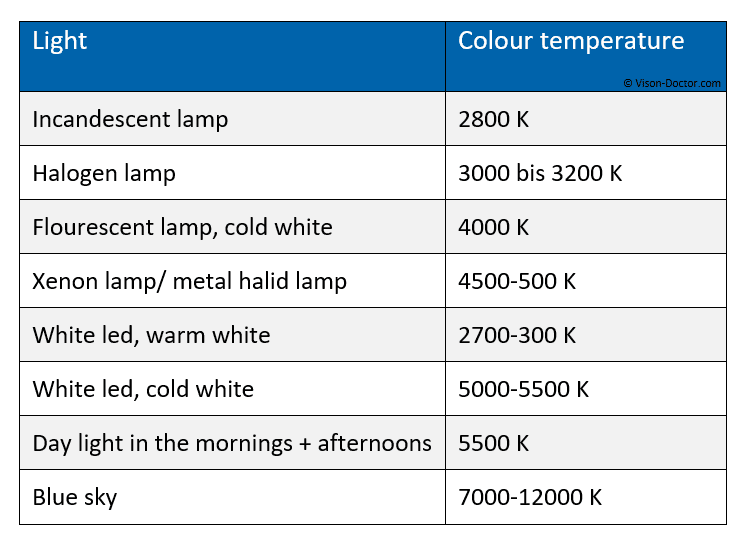

The temperature of a colour is measured and indicated in kelvin (K) and is a measure for the colour impression of a light source. The spectrum visible to the human eye ranges approximately between 2,790 and 11,000 kelvin.

The physical explanation for this phenomenon is the definition of a "black body radiator" according to Max Planck. A black body absorbs all incident radiation, i.e. it reflects no radiation. The colour temperature refers to the temperature of the black body which generates the same colour impression as the actually existing lighting.

A black body with a temperature of 5500 K has a radiation spectrum similar to that of daylight in the morning.

|

Each type of illumination has an individual light spectrum with a different distribution over the visible range of wavelengths with different intensity. An incandescent lamp does indeed have a complete spectrum which, however, has a typical bell-shaped intensity distribution of a "black body" radiator. Metal halide lamps, fluorescent lamps and LEDs even have very significant emissions in specific wavelength ranges.

Important for industrial machine vision

- Depending on the "white" lighting used, a differently tinged camera image is created. White LED lights appear strongly bluish, images using fluorescent lights seem to be greenish. Due to the increased red and infrared radiation, halogen lamps cause a very yellowish colour impression in the video image.

- Ambient light and daylight variations significantly influence the colour temperature and should be avoided in case of colour applications. Put an enclosure around your inspection area!

- The sensitivity of the camera sensor is also not identical for different colours. Additional distortion effects can occur.

- These inhomogeneous RGB colour portions can be corrected by means of white balancing. This is partially already done in the camera, on the frame grabber or by using software on the PC.

- Due to the aging process, the colour temperature of the lighting is shifted. Halogen lights will shine darker, therefore they emit more red portions, in case of white LEDs fluorescence dyes are destroyed and the native blue emission becomes increasingly evident. Then a regular calibration is required.

- When using white light, optical errors can appear in the resulting video image, no matter if you use a colour camera or a monochrome camera. The longitudinal and transversal chromatic error may be compensated by high-quality optics in order to avoid these colour or grey fringe effects.

- A simple solution to avoid this effect in case of monochrome cameras is the use of monochromatic light (blue, green, red, etc.) produced by LEDs. Images richer in contrast are the result.