Interactions at the surface

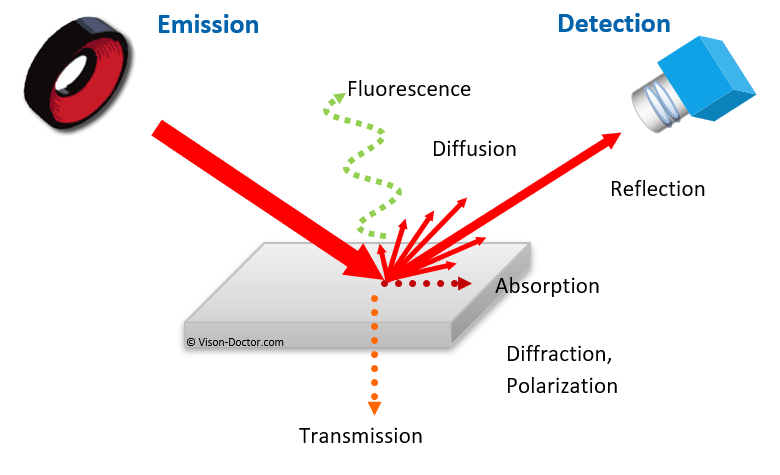

Depending on the material and its surface, a large number of effects appear at the surface in incident light. The incident light is partly absorbed, partly reflected and, depending on the material surface, also strayed. Light can also be absorbed first and then (r)emitted again. This effect is called remission. In case of opaque, semi-translucent or translucent materials, the light can also pass through the body (transmission). In some cases light is even polarised or diffracted at the surface. Some objects can even emit light (illuminated displays, LED segments, indicators), fluoresce in a different light colour or phosphoresce (luminesce).

|

Usually one of these effects never appears alone, but it is always a combination of several effects. However, the emphasis of the individual portions of reflection, straying, absorption, remission, transmission and absorption strongly depends on the material and surface properties:

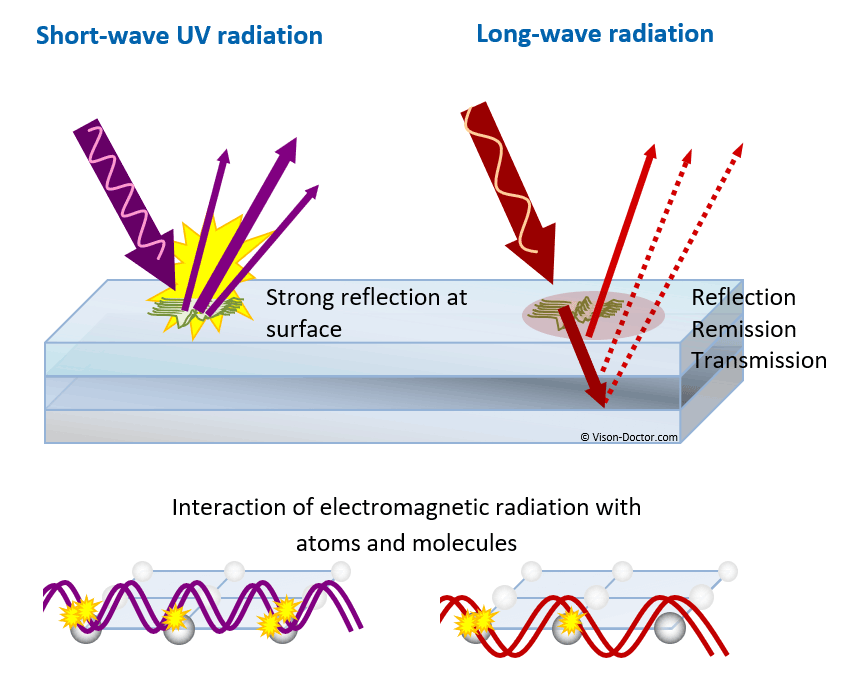

Influence of the wavelength of light on surfaces

The shorter the wavelength of the light used (blue or UV light), the higher is the portion of the stray light at the surface; absorption, remission and transmission are reduced. Surface defects are clearly visible. The longer the wavelength of the light used (red or IR radiation), the more the material is penetrated and surface phenomena visible in the camera image diminish. Viewing below the surface or looking through a body is possible.

|

Examples for light interactions of different materials

- Metals extremely reflect any incident light. If you illuminate metals vertically using direct light sources, the illuminant is often reflected. Tilting the object, illumination or camera can provide a remedy. If metals are brushed, matted or sand-blasted, they stray much light at the surface and the optical inspection is significantly easier. Attention to very finely machined metallic surfaces in circular shape (turned parts, etc.). The light possibly produces a "propeller effect" at the even surface generated by interferences of light. In most of the cases, metals must be illuminated using diffuse lighting. Even and smooth surfaces are suitable for the use of coaxial lighting, curved and strongly textured surfaces must be illuminated using extremely diffuse dome lighting. Two metals of the periodic system and also some alloys are coloured. Gold and gold-coloured objects (e.g. brass), for instance, may appear darker when using blue light. Copper can be made darker using green or blue light according to the principle of subtractive colour mixing. Metals can be made darker in incident light by means of polarisation filters.

- Plastics and foils are mainly dyed and stray and reflect light to a greater or lesser extent, depending on the surface texture. Glossy reflections can be suppressed using polarisation filters. Plastics can also be opaque (semi-translucent) and stray light very well. The shorter the wavelength of the light used, the more the light is strayed and absorbed on the semi-transparent body, long-wave light rather transmits (see transmitted light illumination and IR illumination). Completely transparent plastics let pass most of the light, the object may be made darker using techniques of photoelasticity by means of polarisation. Collimated (parallel) light, too, can possibly create additional contrast in transmitted light.

- Glass: Flat glass is often inspected in transmitted light and creates only rather low contrasts. Very short-wave light can help during inspection. Potentially the bright reflection of the illuminant on the glass itself can be used in order to find defects when using large diffuse illuminated panels at the glancing angle. Other inspection techniques are based on lateral light coupling into glass on a smooth edge. The glass now has the effect of fibre optics, the light is strongly strayed by bad spots, bubbles, etc. and the bad spot appears dark in the camera image. Glass is a challenging test object.

- Mirror glass: : Even an optically high-quality mirror reflects only about 95% of the incident light, further portions are strayed and absorbed at the surface. Surfaces can be lighted using large diffuse illuminated panels, then the reflection of the illuminant is inspected. Surface shapes of curved mirrors, etc. can be inspected by checking attached patterns (dot pattern, grid, stripes on a bright background) and by inspecting the reflection.

- Ceramics: This material is often characterised by slightly porous structures which can have any colour from translucent or white to black when dyed. Thin slightly translucent ceramics transmit light, absorb and stray large portions of light. Therefore hardly any reflections are to be expected at the surface, however, checking for cracks and finding bad spots using dark field illumination can sometimes be difficult since much light is remitted.

- Paper, cardboard, wood Matt papers and cardboard stray light very well at the surface due to the fine cellulose fibres which are distributed in all directions. Bright papers have a high reflection and remission portion, if they are very thin they also transmit light correspondingly. An imprint on the back may have a disturbing effect. Glossy papers reflect a lot of light at the surface due to the coating layer. Only tilting the direct illumination, the body or the camera provides a remedy in order not to inspect at the glancing angle. Polarisation filters possibly help, too; in case of strongly glossy paper, diffuse illumination is used. Wood strays a large proportion of light so that inspecting the surface is free of problems most of the time. If you want to look deeper into organic materials like wood (or fruits, vegetables), infrared light is often used for the inspection. The light is reflected to a lesser extent and strays and penetrates into the material in order to make bad spots visible.