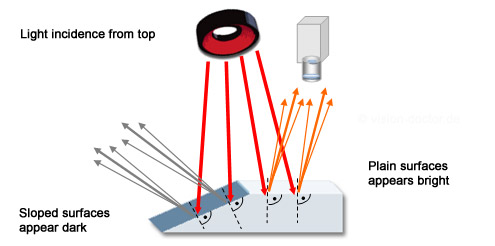

Influence of surface geometry

The surface geometry in combination with the light source seriously influences the resulting video image. Particularly when using aligned dot-shaped light sources, the simple motto "angle of incidence = angle of reflection" applies to the reflected light. This applies especially to collimated incident light (condenser / telecentry principle), as the emitted light is extremely parallel and no diffuse light is emitted. But also diffuse illumination techniques can generate directed light: a diffuse coaxial incident light emits the greater part into one direction.

If the test object is illuminated from above, there is a strong reflection towards the camera, the even part surface shines brightly. Light is refracted to the side at inclined edges, curvatures and phases, they appear dark in the camera image as this light does not incide on the camera sensor.

|

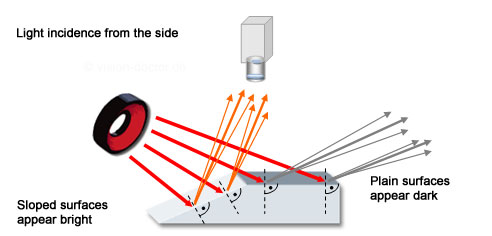

In case of lateral incidence of light, the light is reflected to the side at the even surface of the test object and does not incide on the camera sensor. The surface appears dark. In our example the ring light is arranged in such a way that the inclined phase is directly at the "glancing angle". Light is reflected to the camera, it appears bright.

|

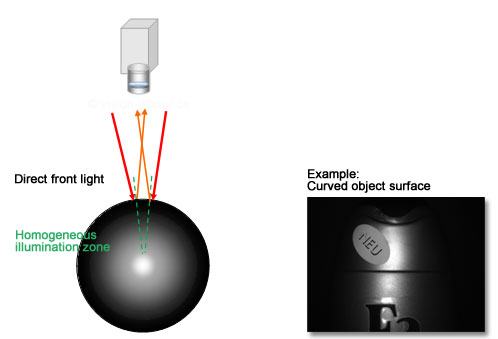

The ideal object to test the influence of the surface geometry on the direction of light is a polished steel ball (simplified also a smooth metallic cylinder). In this way it is easy to see which areas a light can illuminate homogeneously.

Direct, aligned illumination

This lighting technique generates a strong reflection on the smooth surface. Light is mainly reflected. For a dot-shaped illumination, the angle of incidence is equal to the angle of reflection. In case of direct, aligned incident light, e.g. a LED ring light, the solid angle which the light can illuminate is extremely low. The radiation angle of the LEDs is typically 15 degrees, with the brightness distribution not being constant along this angle so that the emitted light seems to be much better aligned.

|

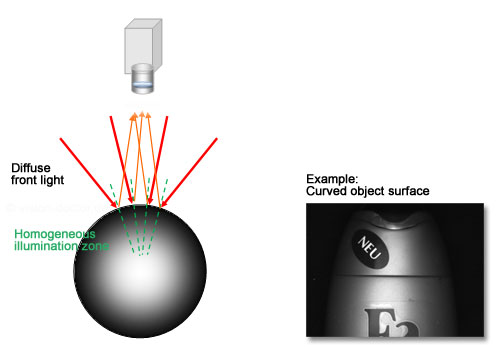

Diffuse incident illumination

The situation gets better the more diffuse the illumination and the larger the illuminated zone. If a diffuse incident light seamlessly illuminates a solid angle of 90 degrees, a homogeneously illuminated image detail of a total of 45 degrees is to be expected. Attention: extensively emitted light does not necessarily have a large illumination angle, if only simple diffuser panels stray the light of dot-shaped light sources.

|

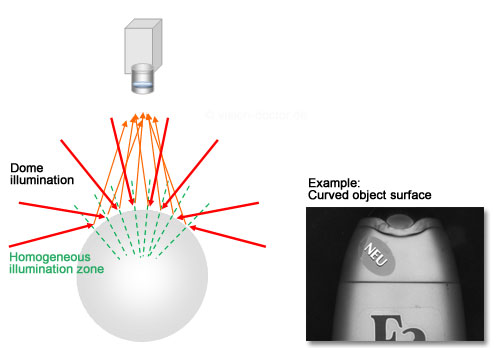

Dome-like illumination

Truly seamless homogeneous light can only be emitted by a spherical dome illumination. The illuminated solid angle on the ball without immersion of the test object into the dome is ideally 90 degrees in case of an illumination of 180 degrees. Even here, significant losses of light towards the margin and clear shading can be observed when illuminating a ball, as the incidence of light without immersion into the illumination dome can be 180 degrees at the maximum.

|