Fluorescent lamps

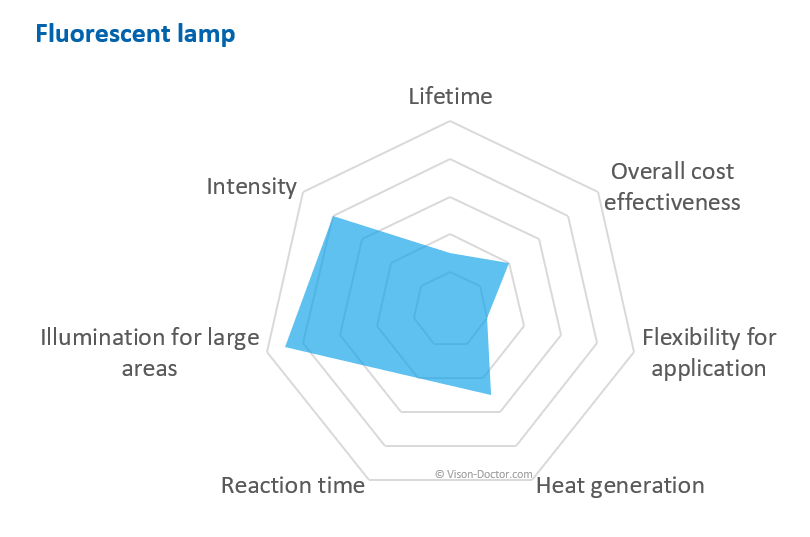

Fluorescent lamps are used in industrial machine vision in order to illuminate large areas. Even complete hall areas, filling and palletising stations and machine units etc. can be illuminated in this way. However, for image processing they should always be used in combination with an electronic ballast to avoid flickering effects in the resulting camera image. They are actually only in use in rod shape, circular-shaped tubes are quite rare.

Video: 50 Hz-flickering of fluorescent illumination in slow motion

Typical properties used in industrial machine vision

|

Functional principle of a fluorescent lamp

Fluorescent lamps are also commonly referred to as "neon light" or fluorescent light. The fluorescent lamp is based on the principle of a low-pressure gas discharge lamp. A noble gas (neon / argon) together with some mercury vapour is ionised by means of an ignition voltage. In this way, the mixture becomes electrically conductive, a high-energy low-pressure plasma is generated.

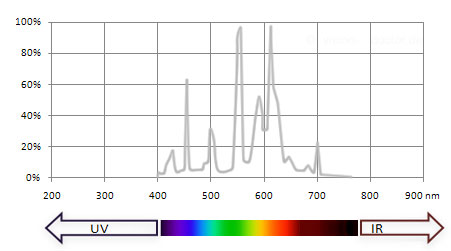

This possibility to generate light is based on electron transitions within the atomic structures of the gas mixture. Exited electrons pass over from higher energy levels to lower ones and in doing so they emit mainly ultraviolet light. Because of the very discrete atomic transitions rather narrow-banded emission spectra are typical for gas vapour discharge lamps.

|

In order to generate visible daylight, the tube is coated with fluorescent substances (= luminescent material) on the inside.

These coatings absorb the unwanted UV light and emit different colours, depending on the gas filling of the tube and the coating. The tubes are available commercially in different shades of white (e.g. warm white, neutral white, daylight white, etc.). Coloured light is also possible, but not very often used for industrial image processing.

Important for industrial machine vision

- Neon light never generates a continuous emission spectrum, but consists of different individual wavelength bands.

- Despite the apparently long service life of several thousand hours, significant losses in brightness must be accepted after a few months of continuous operation. This problem can be solved by a cyclically replacing the tubes. As one lamp often contains several tubes, they are replaced temporally shifted. If approx. 4 tubes are installed, one of the tubes is replaced every four to six weeks. On average, the tubes remain in operation for 4 to 6 months in this way. Age, brightness, colour temperature, etc. are always a mix of several tubes.

- An electronic ballast is stringently required for the use of fluorescent lamps. The typical 50Hz flickering effect is very disturbing for any proper inspection, by using a 25 kHz ballast these problems can mainly be avoided.

- The longer the operating time, the more the fluorescent layer is particularly damaged which converts UV light into visible light. Over the course of time, the lamp will emit rather shorter-wave light. For critical colour applications, a white balance should be performed periodically and the individual tubes should regularly be replaced in a cyclic mode.